All weather coats

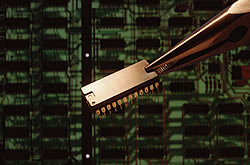

A range of industrial sectors produce products, the main material of which has been coated by another material. The coating technique alters the characteristics of the core material in such a way that its main behaviour remains intact while some properties are improved. Thin films of materials, in the magnitude of micron, are added on other materials enhancing their properties in terms of hardness, friction, thermal protection, corrosion resistance etc. The ISOTECH project aimed to develop and optimise coatings for different applications. In order for this to be achieved a system consisting of one deposition and one control unit was developed. The deposition unit utilises the closed film unbalanced magnetron sputtering technique while the in-situ control was performed by a low-cost, high-speed spectral ellipsometry unit. The advantage of the system is that it optimises the properties of coatings by monitoring continuously the stoichiometry, composition, microstructure and thickness of the depositing film, through the whole deposition process. The system was mainly tested in coating on razor blades, crystal quartz oscillators bearings and seals and it proved able to provide optimum coating properties at the highest possible reproducibility. Thin film science has grown world-wide into a major research area. The explosion of innovations in sectors such as microelectronics, optics, nanotechnology and aerospace goes hand-in-hand with thin film processing technologies. In this context the coating system developed provides evidence of further success for the application of improved thin film processing technologies.