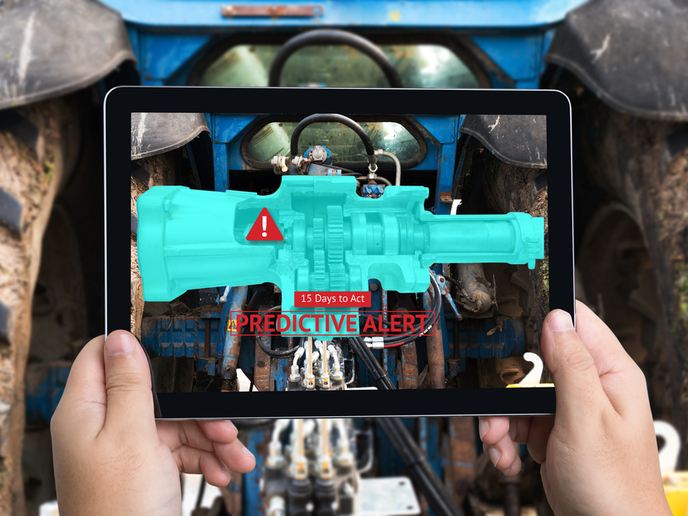

Monitoring industrial process equipment

A European consortium designed the continuous corrosion surveillance system as a solution to costly forced installation outages caused by corrosion degradation. This innovative system permanently monitors the condition of process installations, such as reactors, storage vessels, water circuits, heat exchangers, piping and pipelines. It aims at decreasing installation down time as a result of the damaging effects of corrosion in industrial processes. The continuous corrosion surveillance system has been tested in industrial environments and relies on novel electrochemical sensing technologies. These electrochemical techniques, such as electrochemical frequency modulation (EFM) and electrochemical emission spectroscopy (EES) facilitate on-line monitoring of uniform and localised corrosion. Also, the system utilises NDE technologies and develops software tools for "integral" corrosion monitoring and inspection management. This facilitates the expert evaluation of monitoring data and leads to on-line real-time diagnostics. Furthermore, the consortium also designed enhanced data processing software and a corrosion management tool. This tool functions with the software shell of the ALIAS system that also consists of new modules for corrosion monitoring and NDT analysis. A key innovation of the corrosion system is the incorporation of the latest "Flash Programmable" RISC based microprocessor technology. This technology enables parallel software and hardware development and leads to decreased development time. In addition, the unit combines both new and existing technology which results in a unique application currently unavailable in today's market.